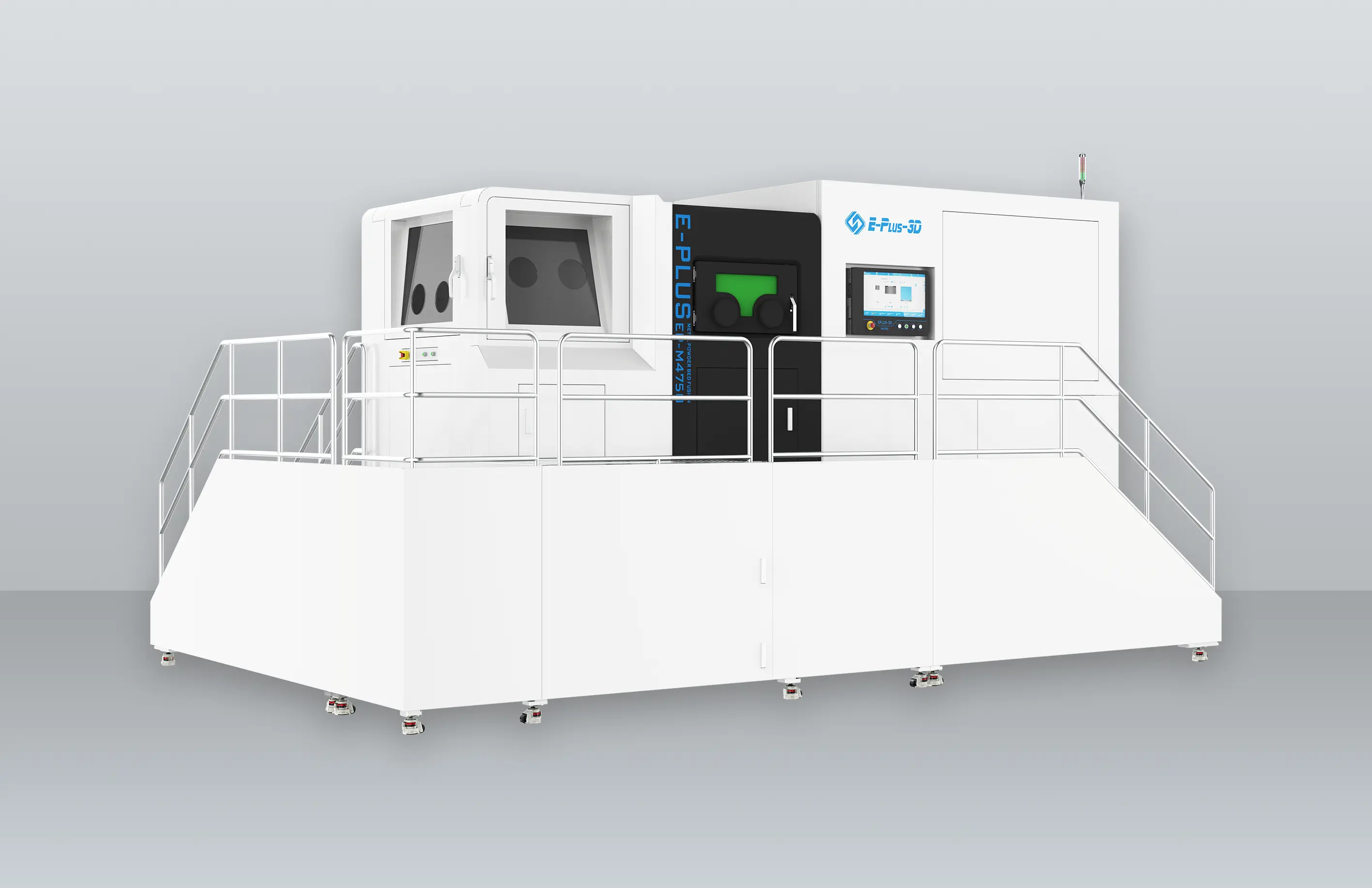

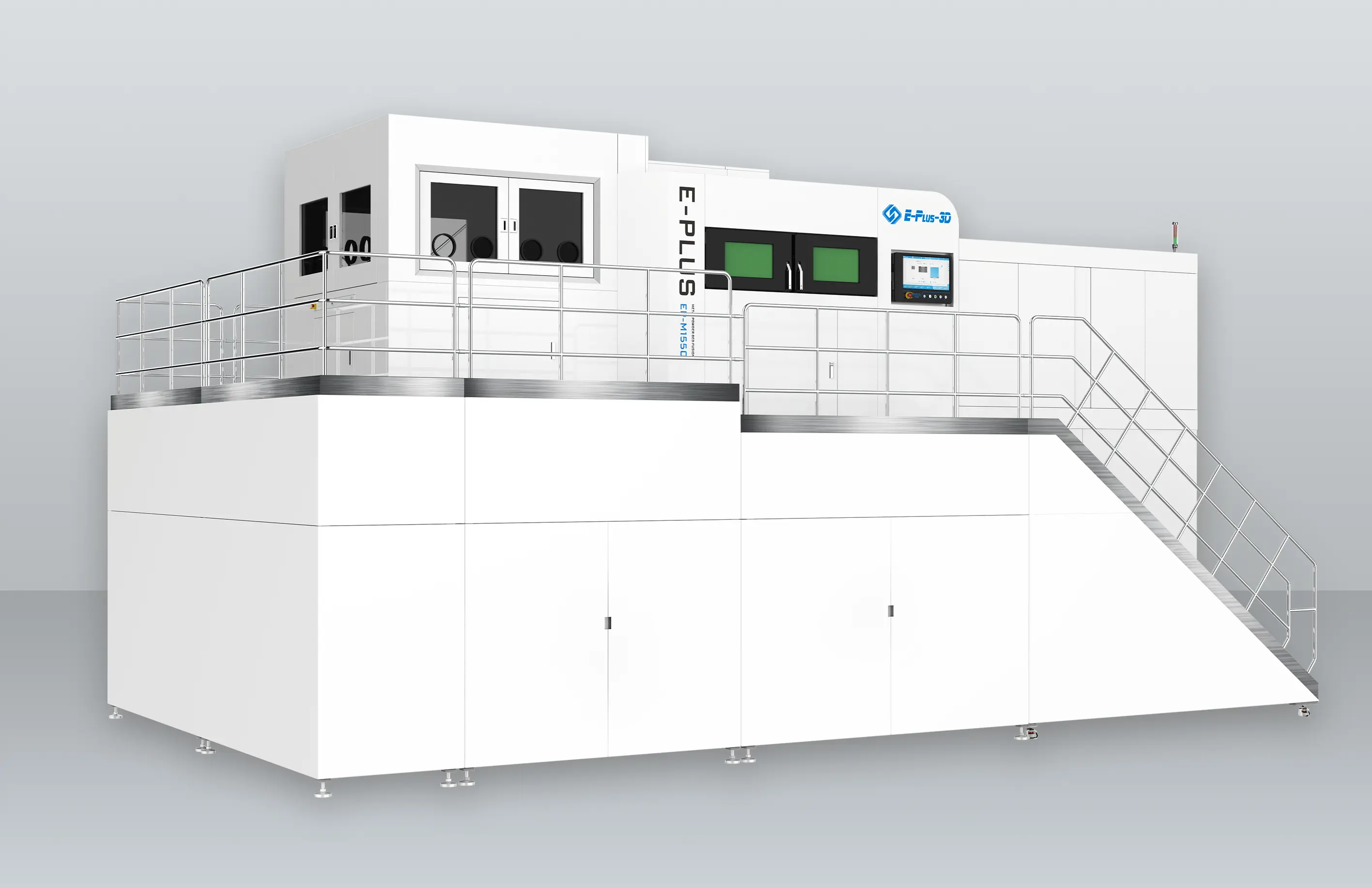

Frankfurt, Germany – November 2025 – Eplus3D, one of the world's large-format metal PBF machine manufacturers, successfully concluded a highly impactful showcase at Formnext 2025, the world's leading exhibition for AM technologies. From November 18th to 21st, Eplus3D attracted visitors to Booth 12.0-E101 with a powerful demonstration of live printing and its latest innovations, headlined by the official launch of the new EP-M550 metal PBF machine. This advanced system is part of a suite of additive manufacturing solutions designed to redefine production efficiency and scalability.

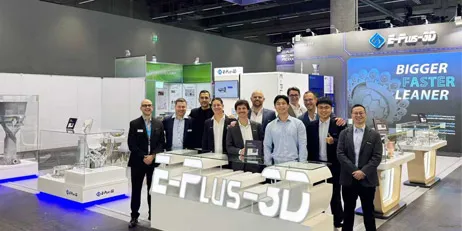

Eplus3D's presence at Formnext 2025

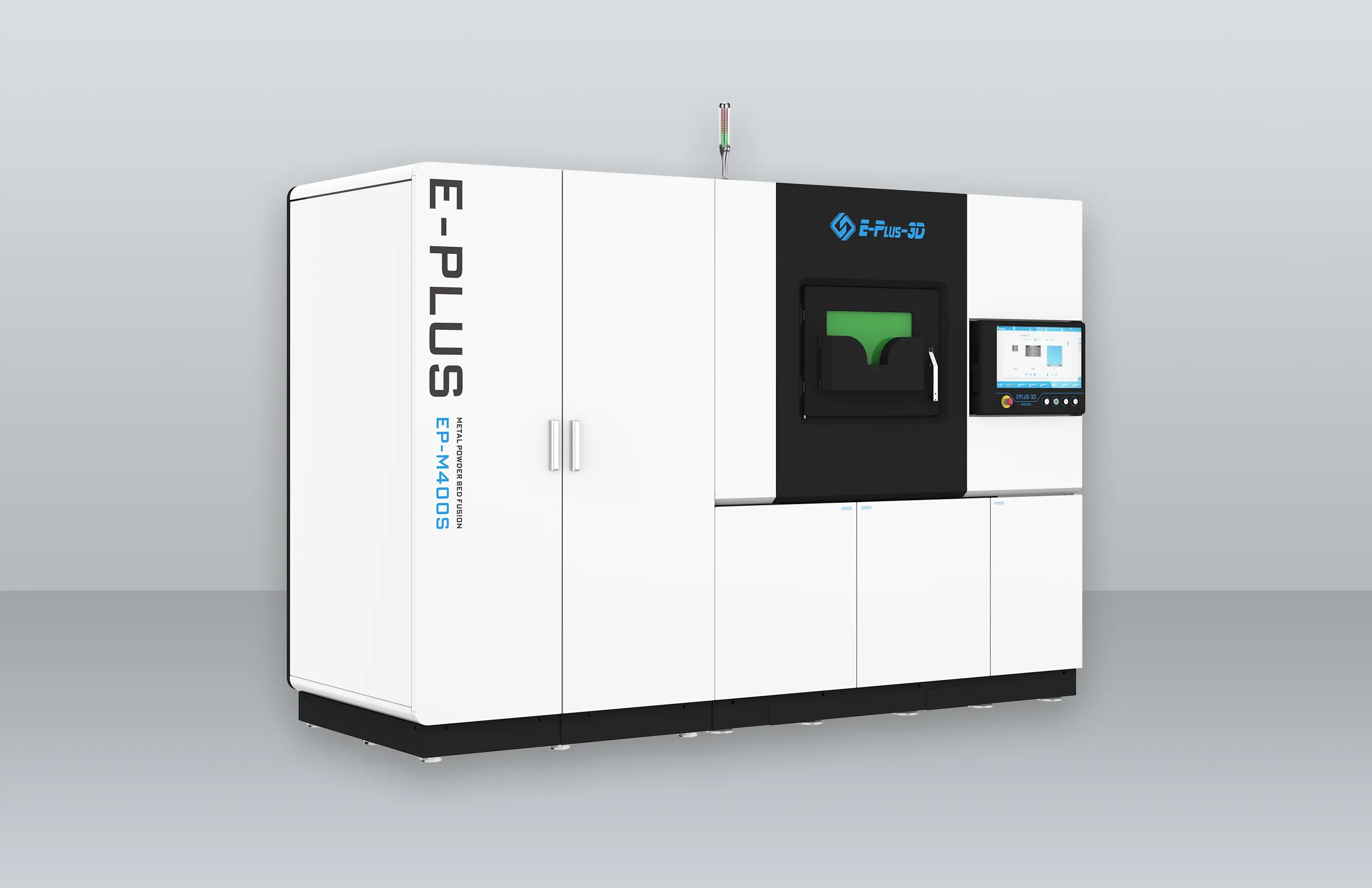

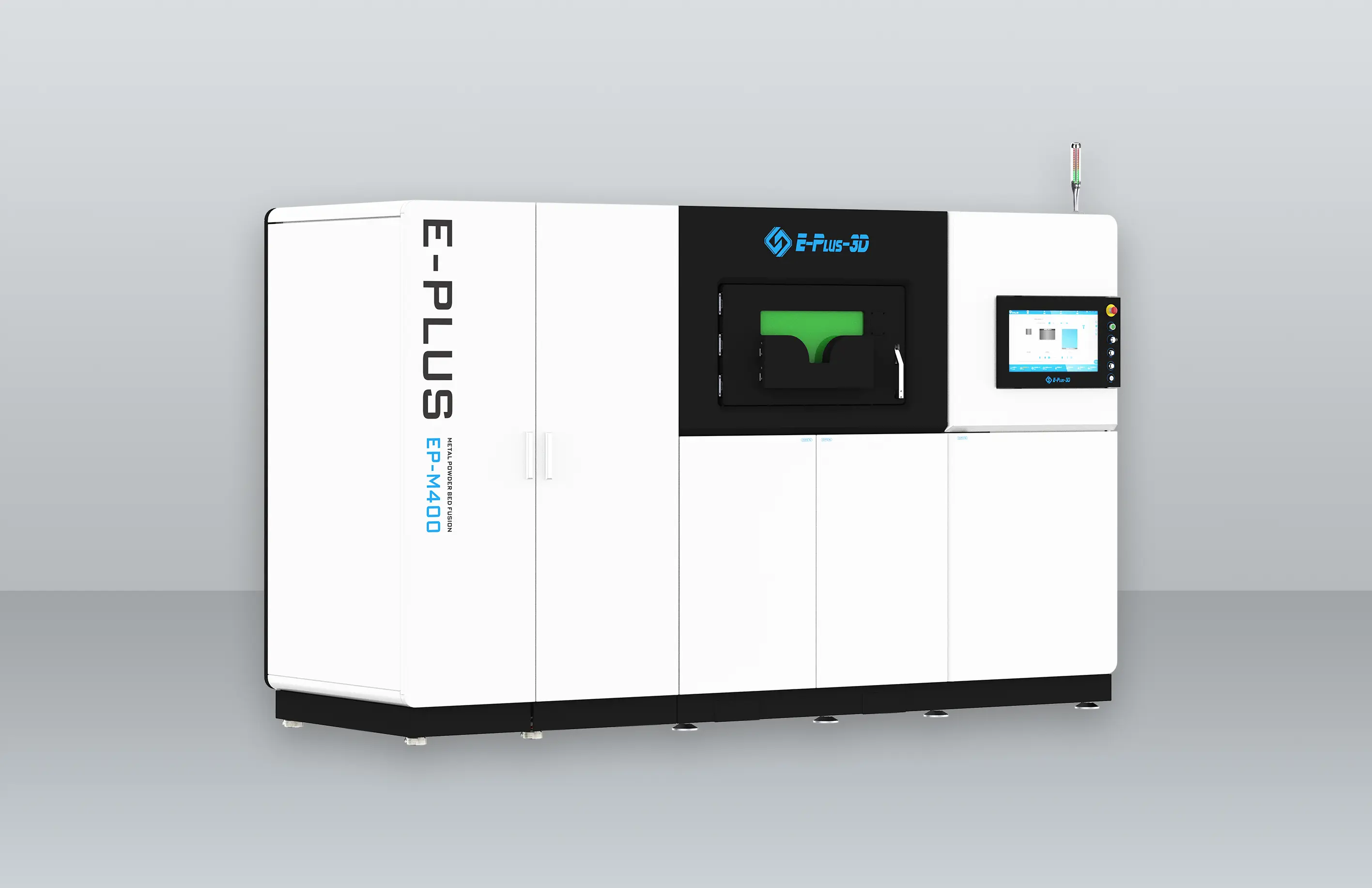

Eplus3D's booth served as a dynamic platform for industry professionals to experience firsthand our expanding capabilities in metal 3D printing. A key attraction was the live printing demonstration on the EP-M400S metal PBF machine, which highlighted the reliability and stability of Eplus3D's equipment in action.

Customers watching EP-M400S live printing

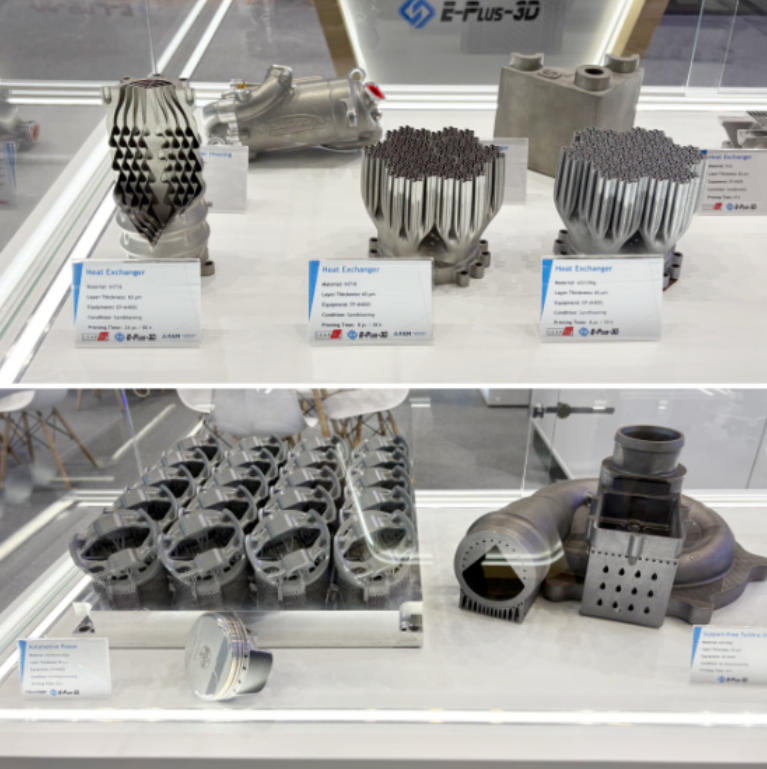

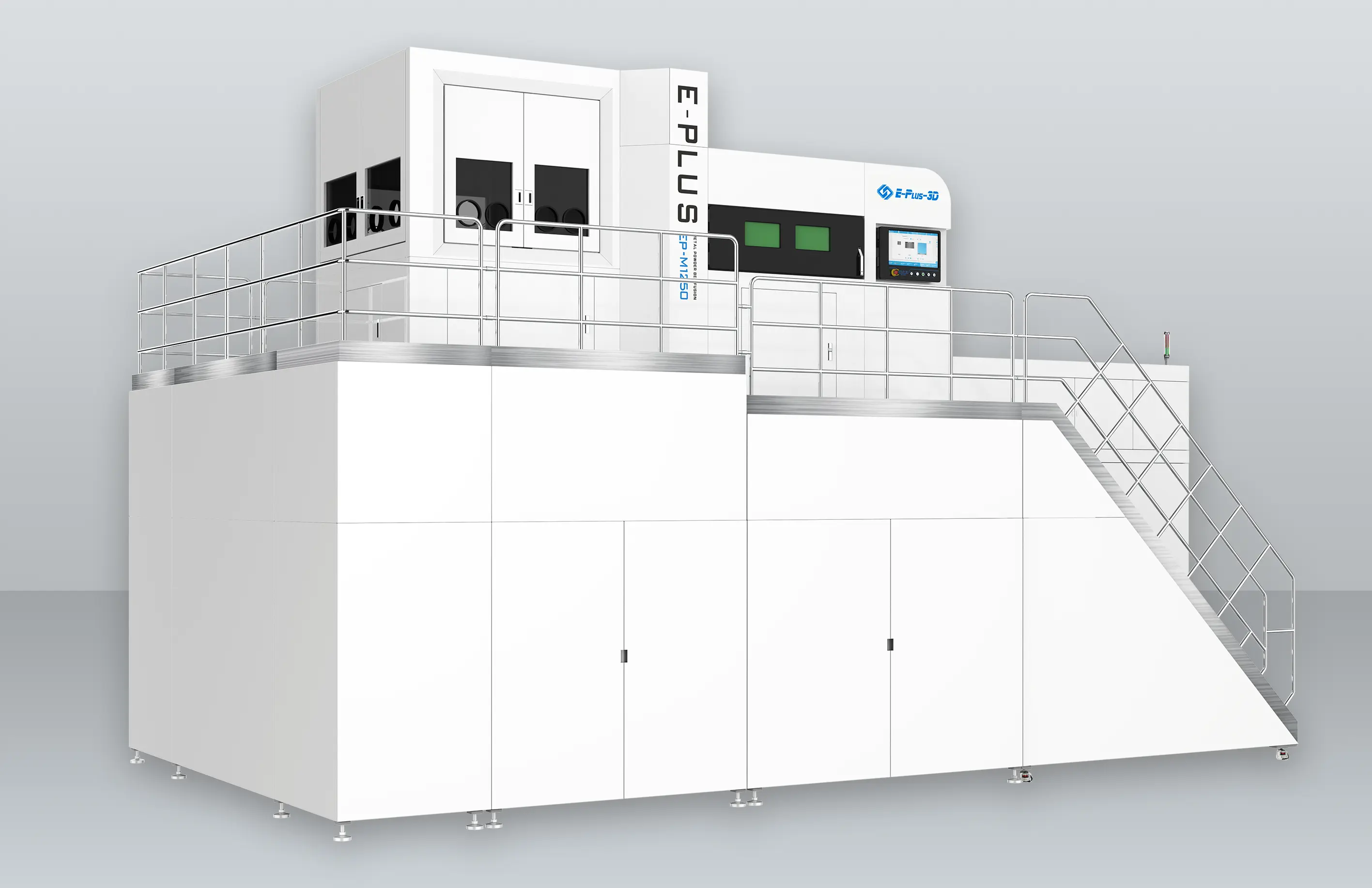

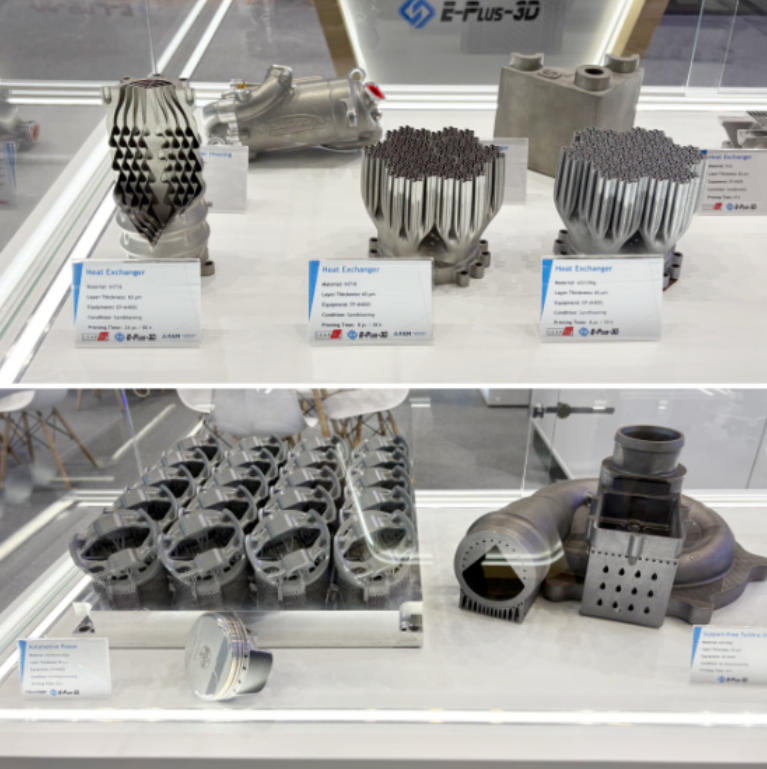

The theme of "Bigger" manufacturing was evident throughout the exhibition - from visual displays to a series of sizable printed components. This emphasis reflects Eplus3D's ongoing innovation in producing large-size, batch-ready parts for sectors such as aerospace, automotive, healthcare, and mold making.

Components showcase at Formnext 2025

A standout technical achievement this year has been our breakthrough in copper and copper alloy printing. By leveraging a high-power red laser process, optimized parameters, advanced scanning strategies, and controlled atmosphere printing, Eplus3D has successfully produced a variety of large-size copper components—showcasing both dimensional capacity and process precision.

Components showcase at Formnext 2025

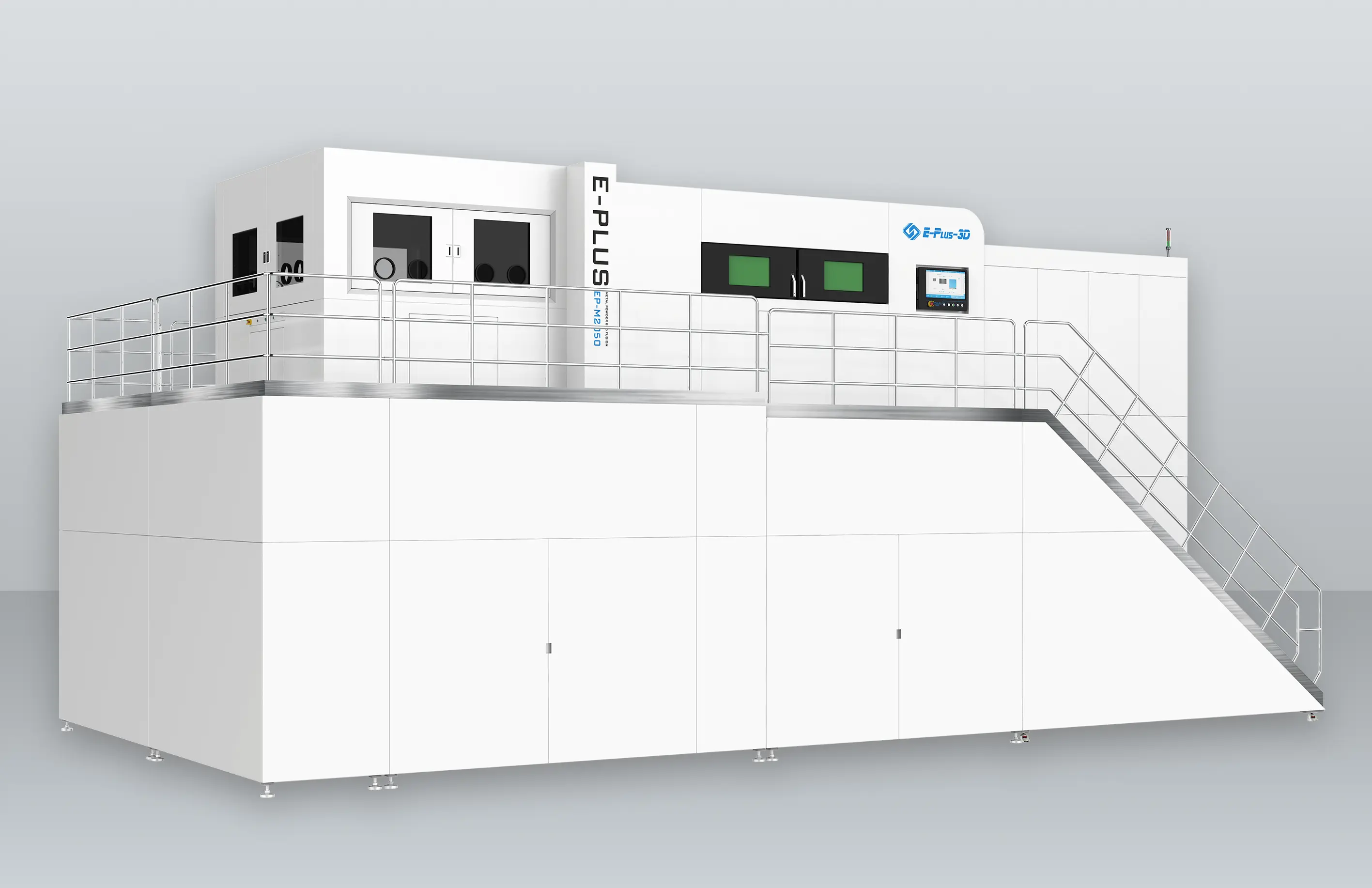

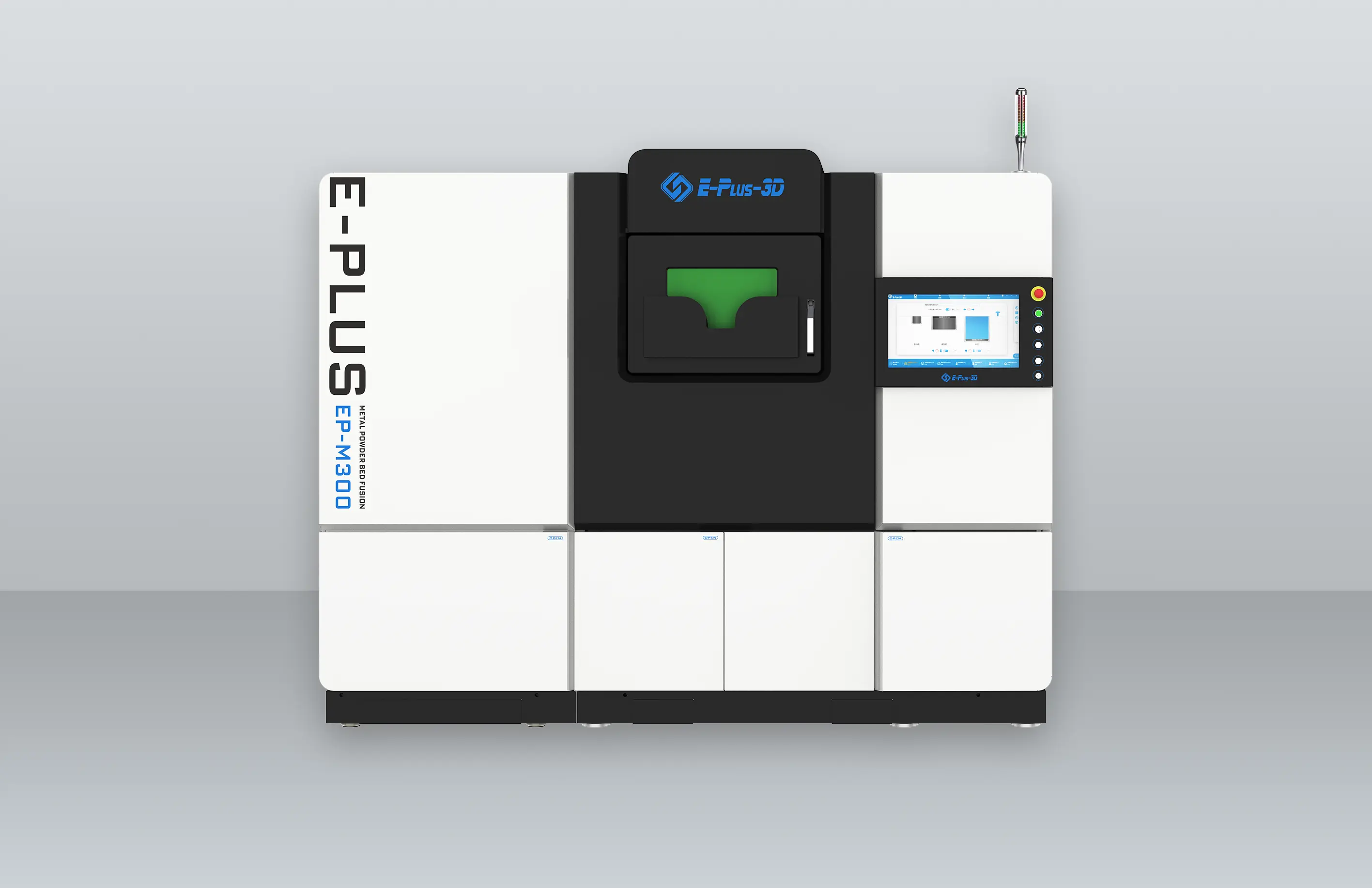

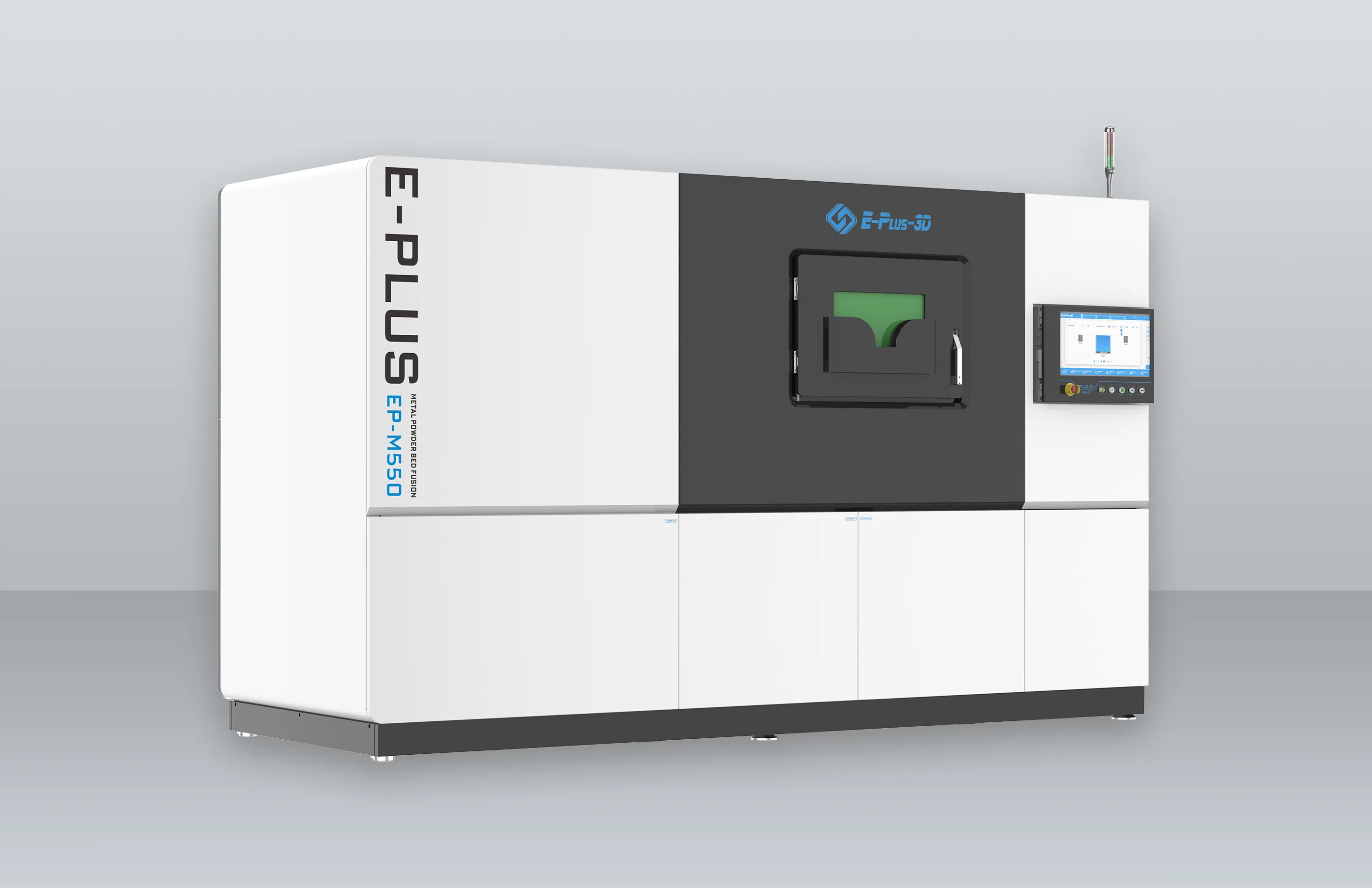

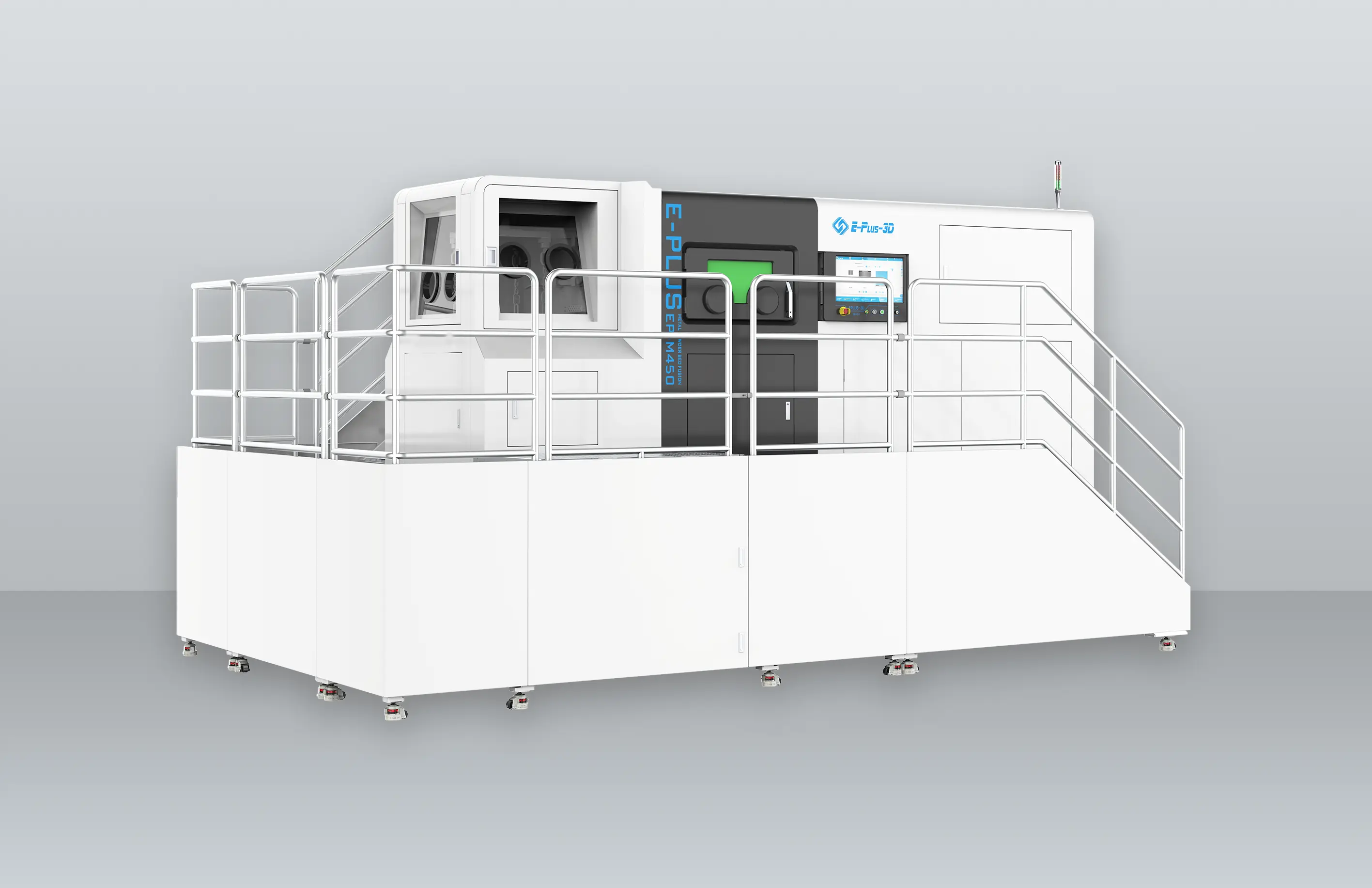

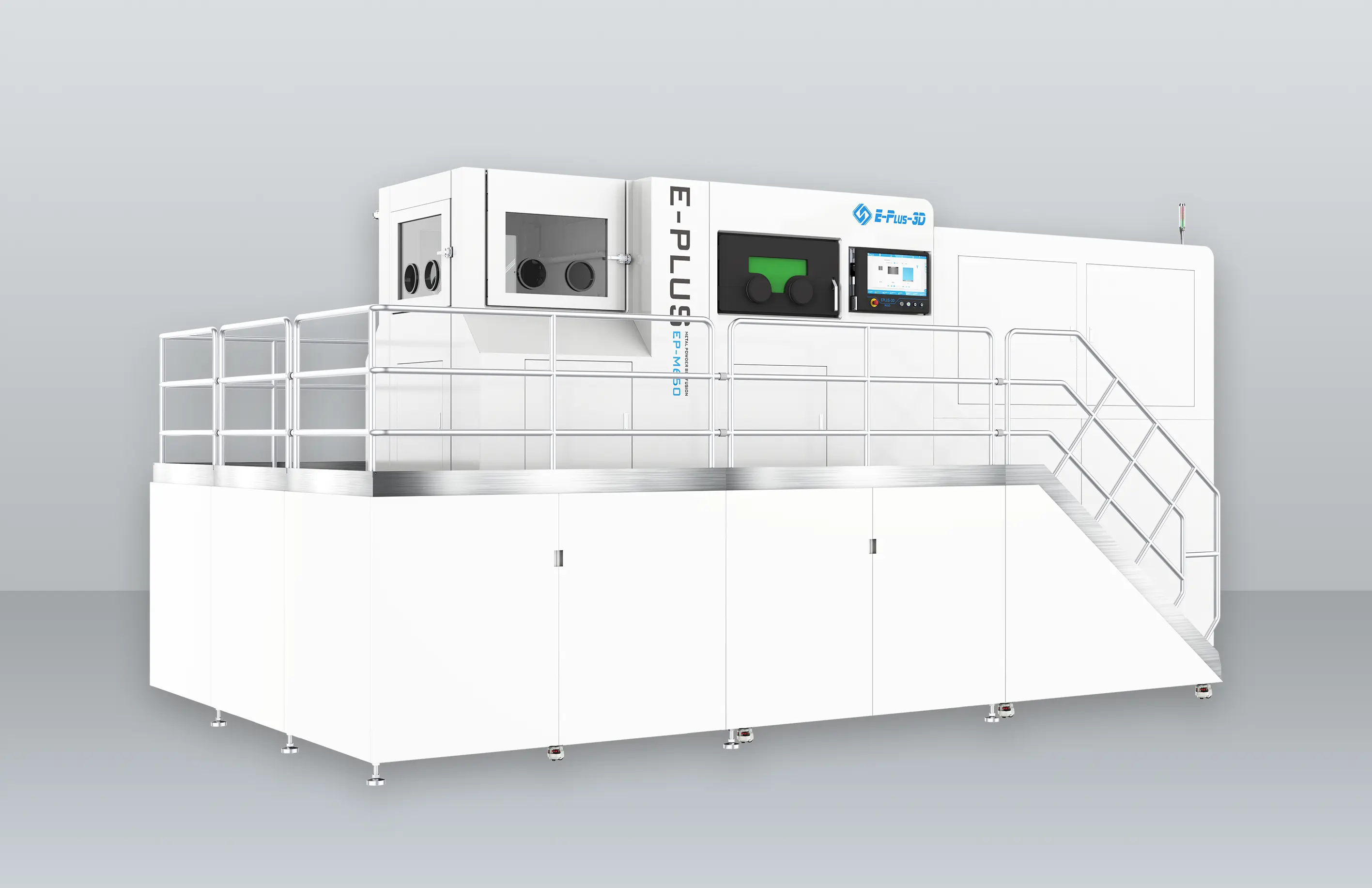

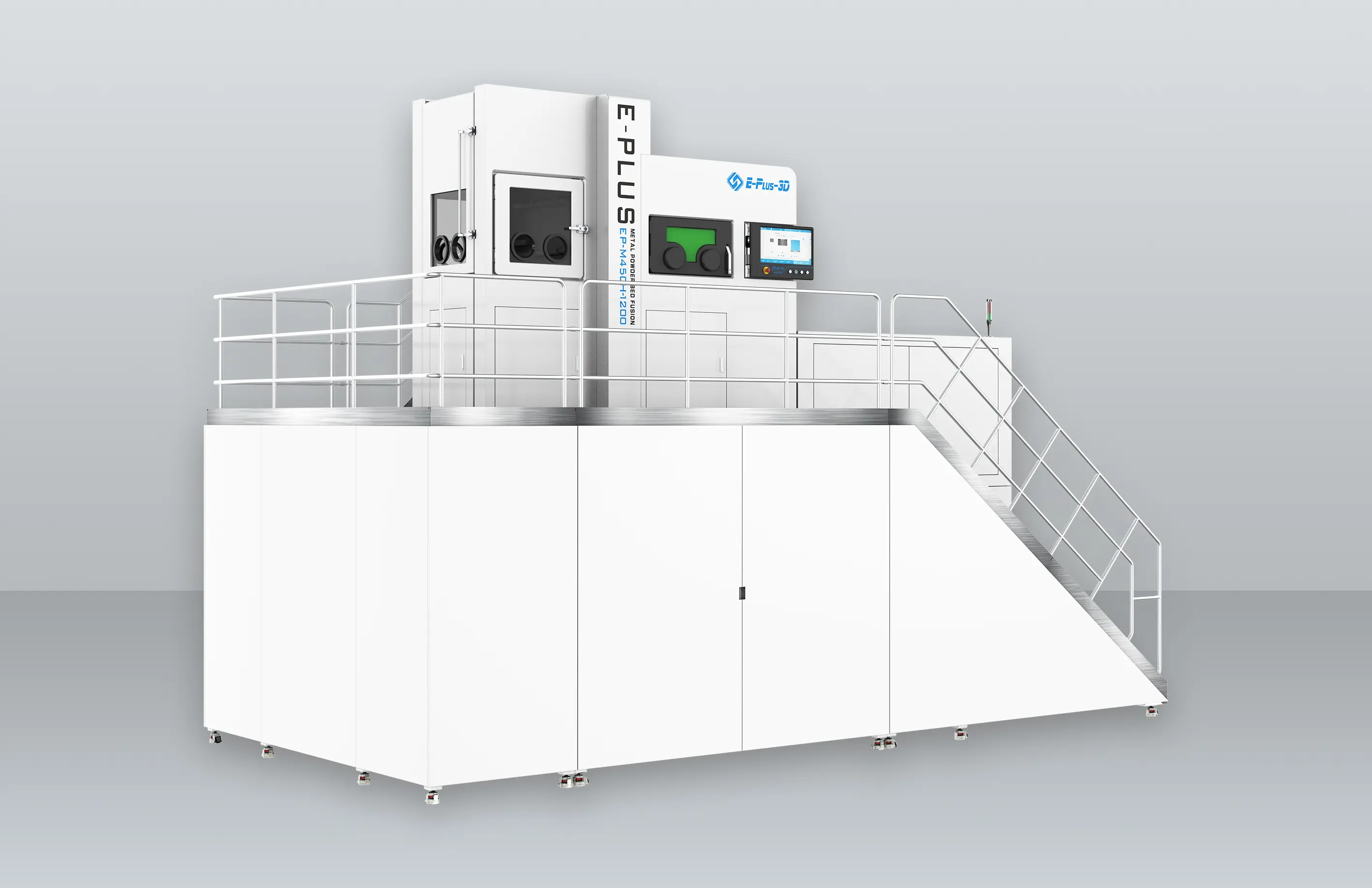

The centerpiece of Eplus3D's presentation was the introduction of the new EP-M550 metal PBF machine, featuring a generous build volume of 550 x 550 x 450 mm and flexible laser options, yet is housed in a remarkably compact footprint of only 7.6 m² (4000 x 1950 x 2840 mm). The EP-M550 effectively bridges the market need for high-speed multi-laser printing within a space-saving design, which makes it an ideal choice for customers whose layout efficiency is paramount.

Highlights of the EP-M550

The performance of systems like the EP-M550 is powered by Eplus3D's core technologies:

Closed Loop Powder System ensures the highest material utilization by fully automating powder handling, which translates into significant time savings, enhanced process automation, and improved operational safety for producing precision metal parts.

Multi-laser Synergy Technology incorporates a customized optical path system to deliver exceptional productivity and efficiency in a compact footprint, advancing the state of the art in metal 3d printing.

Compare to traditional manufacturing methods, these advancements provide a robust foundation for high-throughput, cost-effective manufacturing, reducing both operational costs and time for our customers through integrated additive manufacturing solutions.

Customers at Eplus3D's booth

Eplus3D extends its sincere gratitude to all visitors, partners, and industry peers who joined us at the booth. The fruitful discussions and connections made at Formnext 2025 reinforce our commitment to driving the AM industry forward through continuous innovation and strong global collaboration.

Eplus3D global team at Formnext 2025

Looking ahead to 2026, Eplus3D will continue to pioneer the next wave of AM technology, focusing on smarter, more integrated, and sustainable metal PBF solutions to further empower our global partners.