Introduction:

Eplus3D, in collaboration with University College London (UCL) and the student-led UCL Rocket team, has successfully designed and additively manufactured Excelsior - a regeneratively cooled, bipropellant rocket engine for the UK’s Race 2 Space 2025 competition. Manufactured in AlSi10Mg using Laser Powder Bed Fusion (LPBF) on the EP-M400S quad-laser system, the project demonstrated how additive manufacturing enables advanced cooling channels, integrated features, and rapid development. As technical partner, Eplus3D provided process consultation, and manufacturing execution for Excelsior’s complex thrust chamber and injector components. Excelsior achieved its target thrust of 5 kN during hot-fire testing, ranking fourth in the Nitrous Bipropellant category, and was one of only eight engines out of seventeen to survive all tests.

UCL Rocket:

UCL is a global top 10 university located in the heart of London, renowned for its world-leading research and education. At UCL Mechanical Engineering, research is driven by the ambition to address some of society’s most pressing challenges - from developing next-generation propulsion systems to support the decarbonisation of transport, to designing medical devices that improve patient care and quality of life.

Central to UCL Mechanical Engineering’s teaching is MechSpace - a dedicated suite of teaching labs and workshops where students gain hands-on experience in design and prototyping. Whether for coursework or student-led extracurricular projects such as those of the six UCL Racing (UCLR) teams, MechSpace provides the tools and environment for students to innovate and collaborate across a wide range of domains, including rocketry, drones, autonomous rovers, submarines, and Formula Student cars. This emphasis on practical engineering is reflected in consistent success at the Institute of Mechanical Engineers (IMechE) Design Challenge, where UCL first-year students have won the national title four consecutive years - and are aiming for a fifth consecutive victory later this year. Eplus3D joined the project as the technical manufacturing partner, providing design-for-additive-manufacturing consultation and executing the LPBF build at its German facility.

Technical Challenges:

The project presented several technical challenges. Temperatures in the combustion chamber exceeded 2,500 K, requiring a robust cooling strategy to prevent material failure. The design included fifty-eight internal coolant channels, coaxial swirl injector elements, and tight dimensional tolerances that demanded advanced manufacturing capability. Material selection had to balance thermal conductivity, mechanical strength, density, and machinability, while the manufacturing process needed to be fast and cost-efficient to meet a student project’s limited timeframe.

Engine Design and Performance:

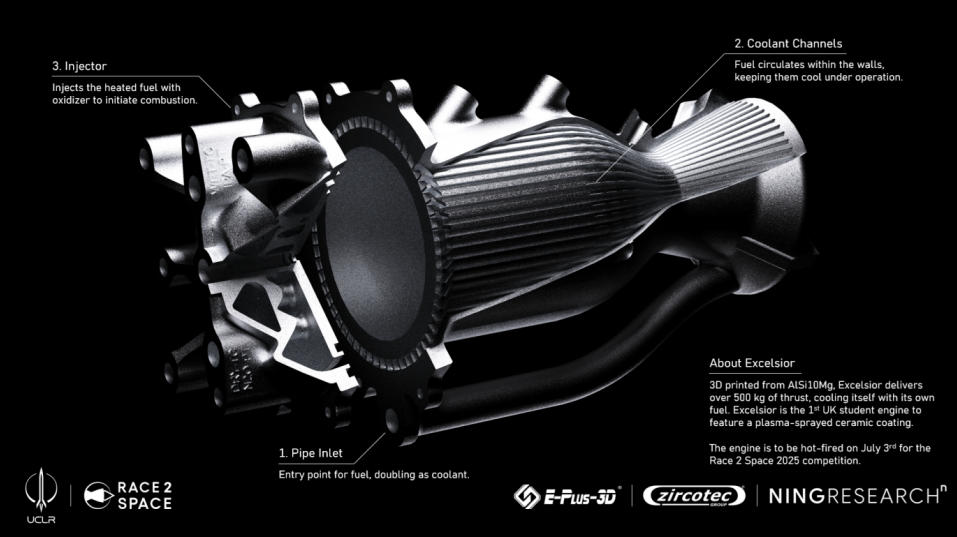

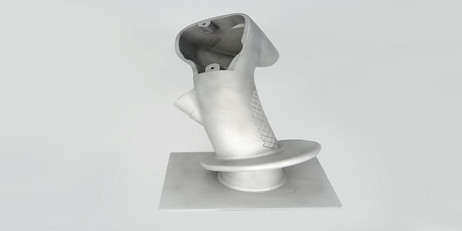

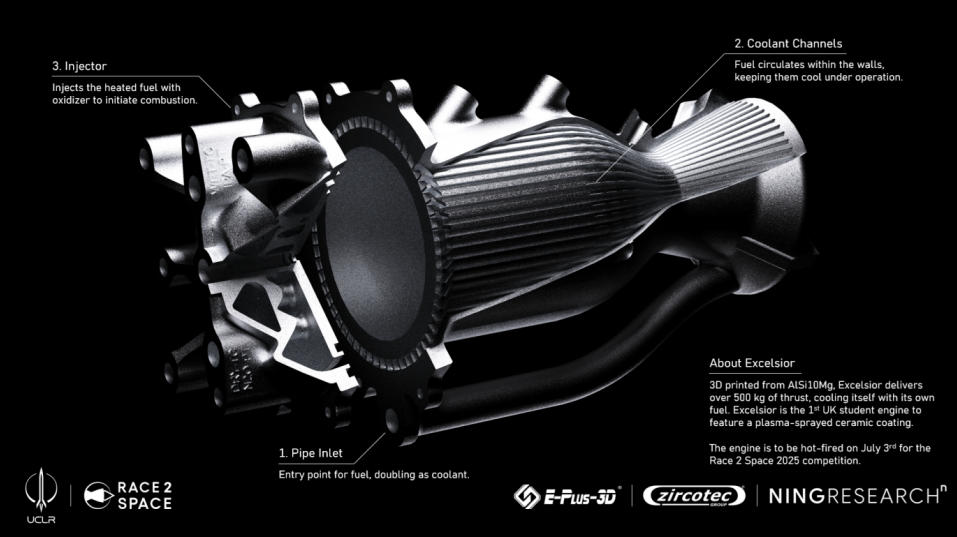

Figure 1 - UCLR Excelsior Engine and Swirl Injector

The Excelsior engine uses Isopropyl Alcohol (IPA) as both fuel and coolant, and Nitrous Oxide (N₂O) as the oxidiser. It is designed for a target thrust of 5 kN, a chamber pressure of 25 bar, and a theoretical specific impulse of 204 seconds. The engine is printed in two parts, the thrust chamber assembly, which includes the chamber and nozzle, and the coaxial swirl injector. These are joined via a bolted flange with Viton O-ring seals for leak-free operation.

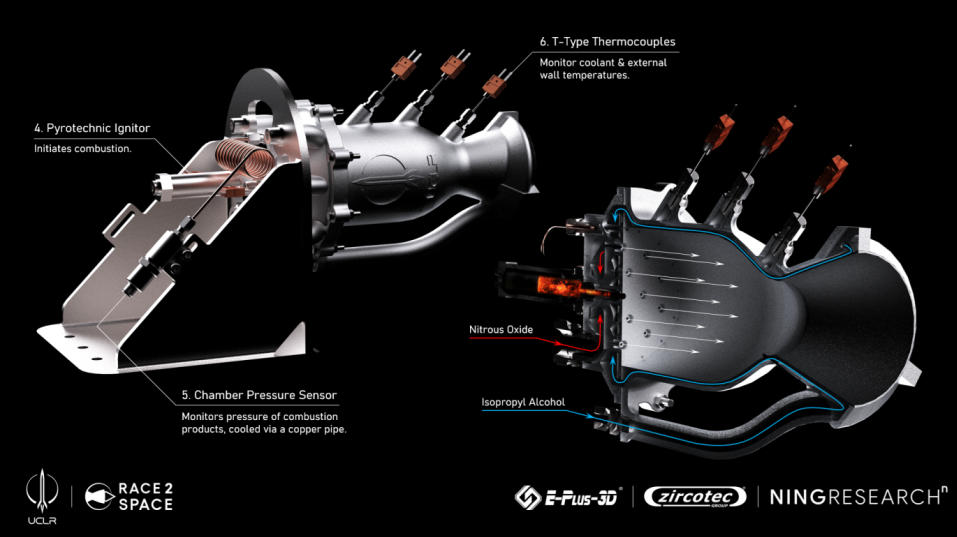

The coaxial swirl injector incorporates fifteen elements. Each element has an inner orifice that delivers N₂O axially into the chamber, surrounded by an outer orifice that injects IPA in a swirling conical sheet. This swirling motion is achieved through three tangential inlet ports feeding a vortex chamber upstream of the orifice, imparting high tangential velocity for rapid atomisation. The geometry was optimised using the Linearised Instability Sheet Atomisation (LISA) model to maximise droplet breakup while maintaining stable operation. Dynamic response modelling was also performed to ensure that injector behaviour under pressure oscillations did not coincide with the engine’s acoustic resonance modes, which could cause combustion instability.

Advanced Cooling Strategy:

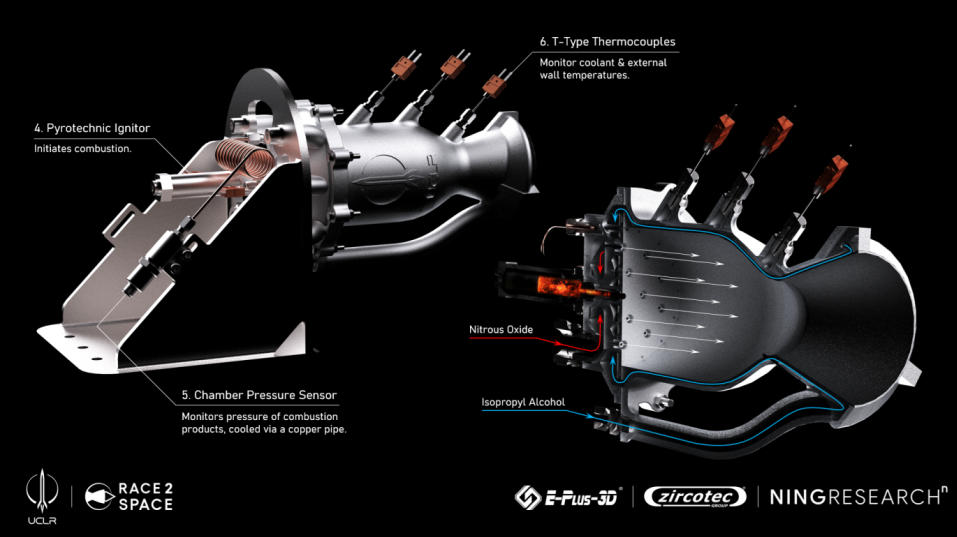

Figure 2 - Engine and swirl injector Full assembly close-up

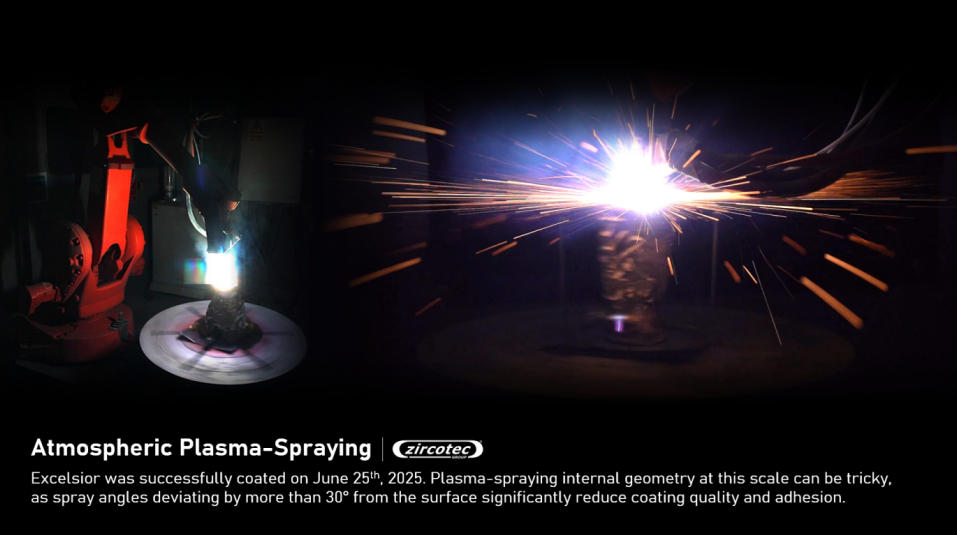

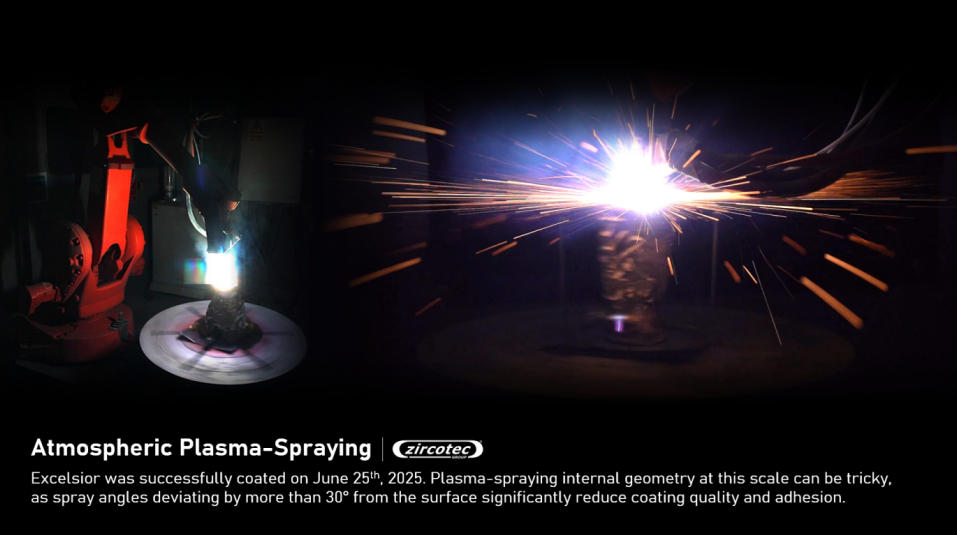

To survive high heat fluxes, Excelsior uses a triple cooling system. Regenerative cooling circulates the entire 0.59 kg/s IPA flow through a printed inlet manifold at the nozzle exit and into fifty-eight axial, single-pass coolant channels integrated into the engine walls. Film cooling is provided by fifteen machined 0.6 mm orifices on the injector face, which direct ten percent of the IPA flow along the chamber wall to form a protective liquid film. Finally, a Zircotec ThermoHold® H2000 zirconia-based ceramic thermal barrier coating is plasma-sprayed onto the inner wall, reducing heat flux and mitigating thermal stress, particularly at the throat - the engine’s most critical region.

Figure 3 - Atmospheric Plasma-Spraying

Material Selection

AlSi10Mg was selected over traditional aerospace alloys such as Inconel 718 and CuCrZr due to its high thermal conductivity of approximately 165 W/m·K after stress relief, which enables rapid heat transfer to the coolant. Its low density of 2.7 g/cm³ allows for significant weight savings, and its machinability supports efficient finishing of sealing surfaces and precision features. The main drawback of AlSi10Mg is its reduction in yield strength at elevated temperatures approaching 600 K, which necessitated detailed thermomechanical stress analysis to verify survivability.

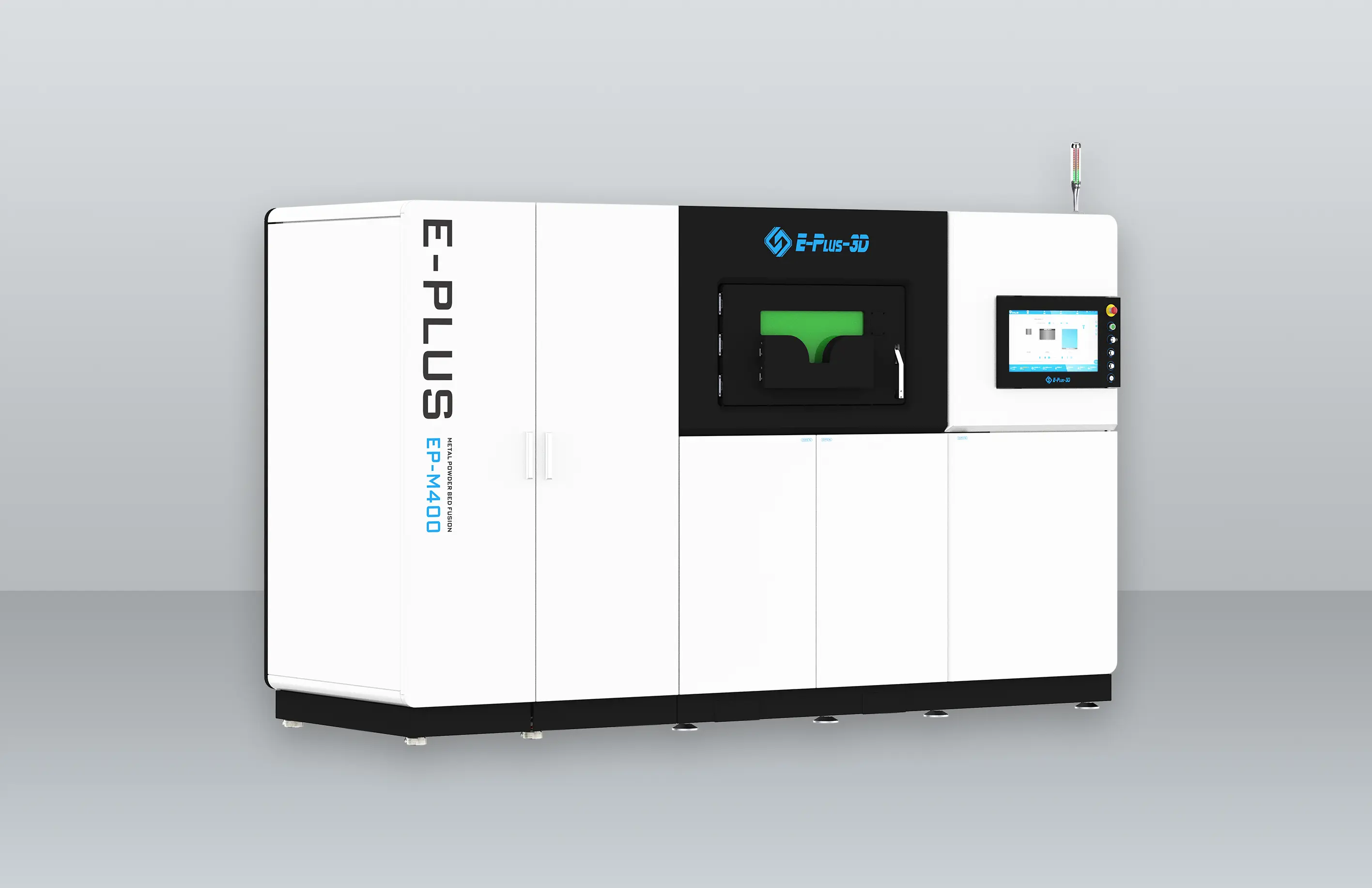

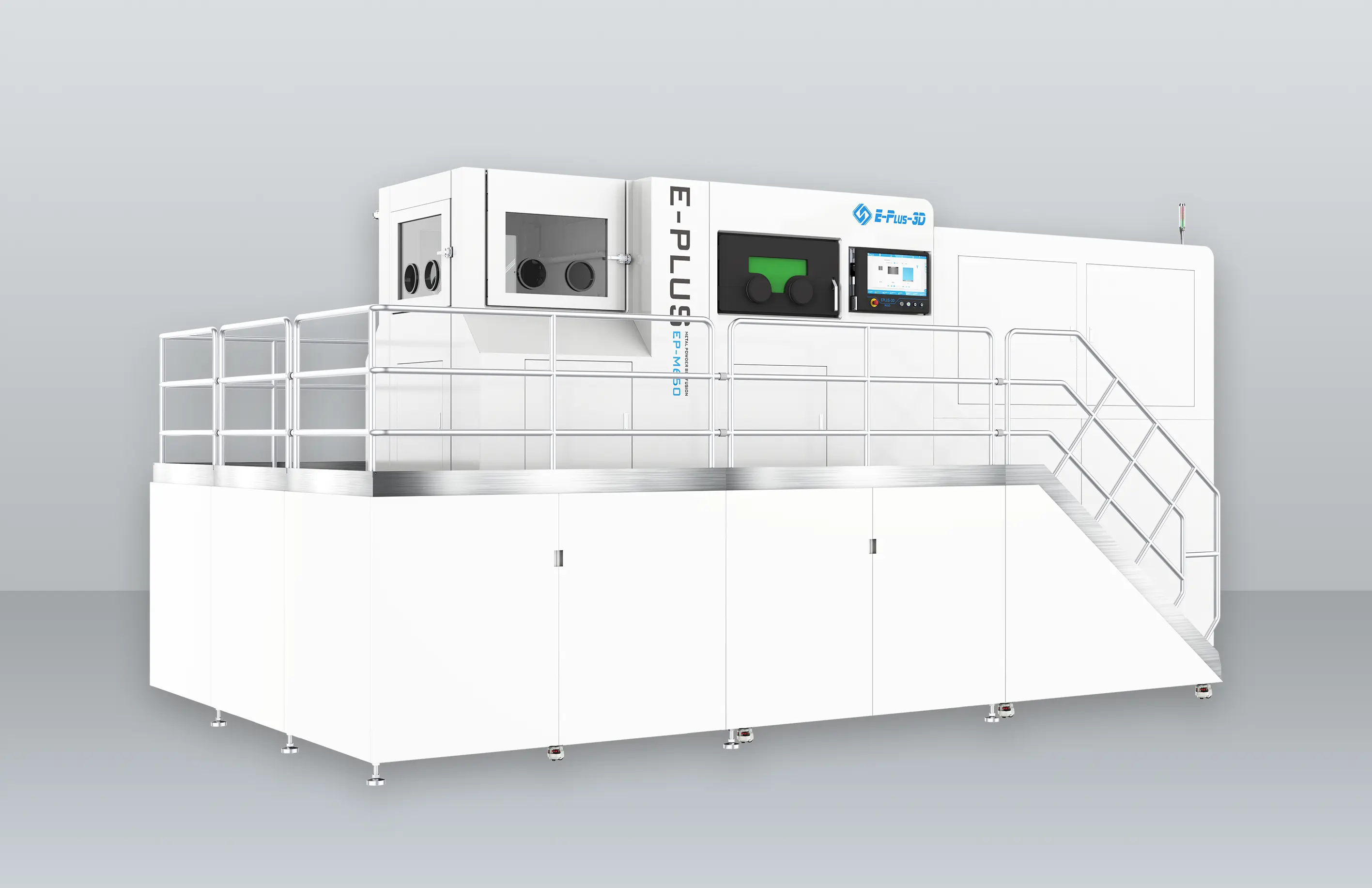

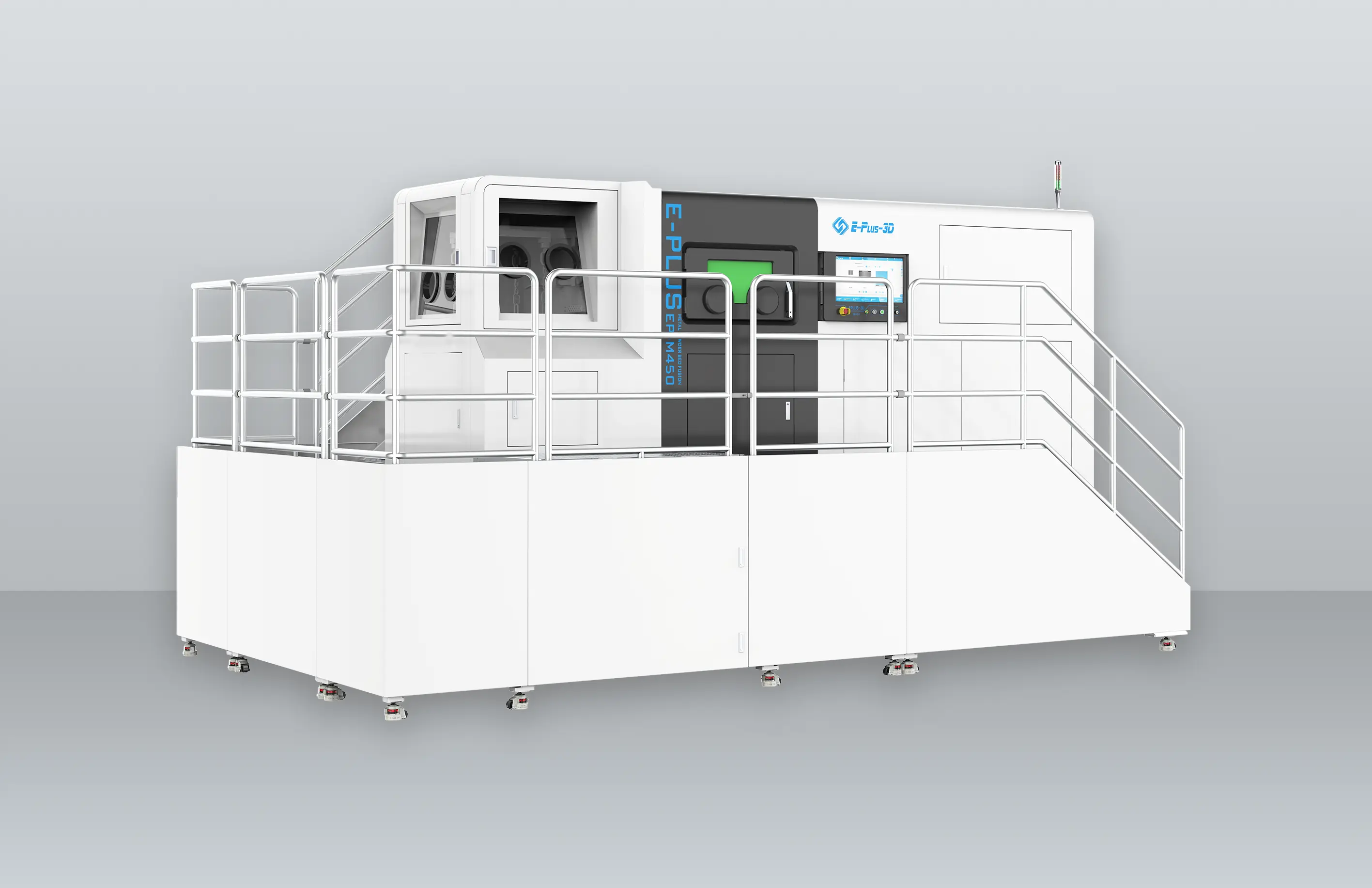

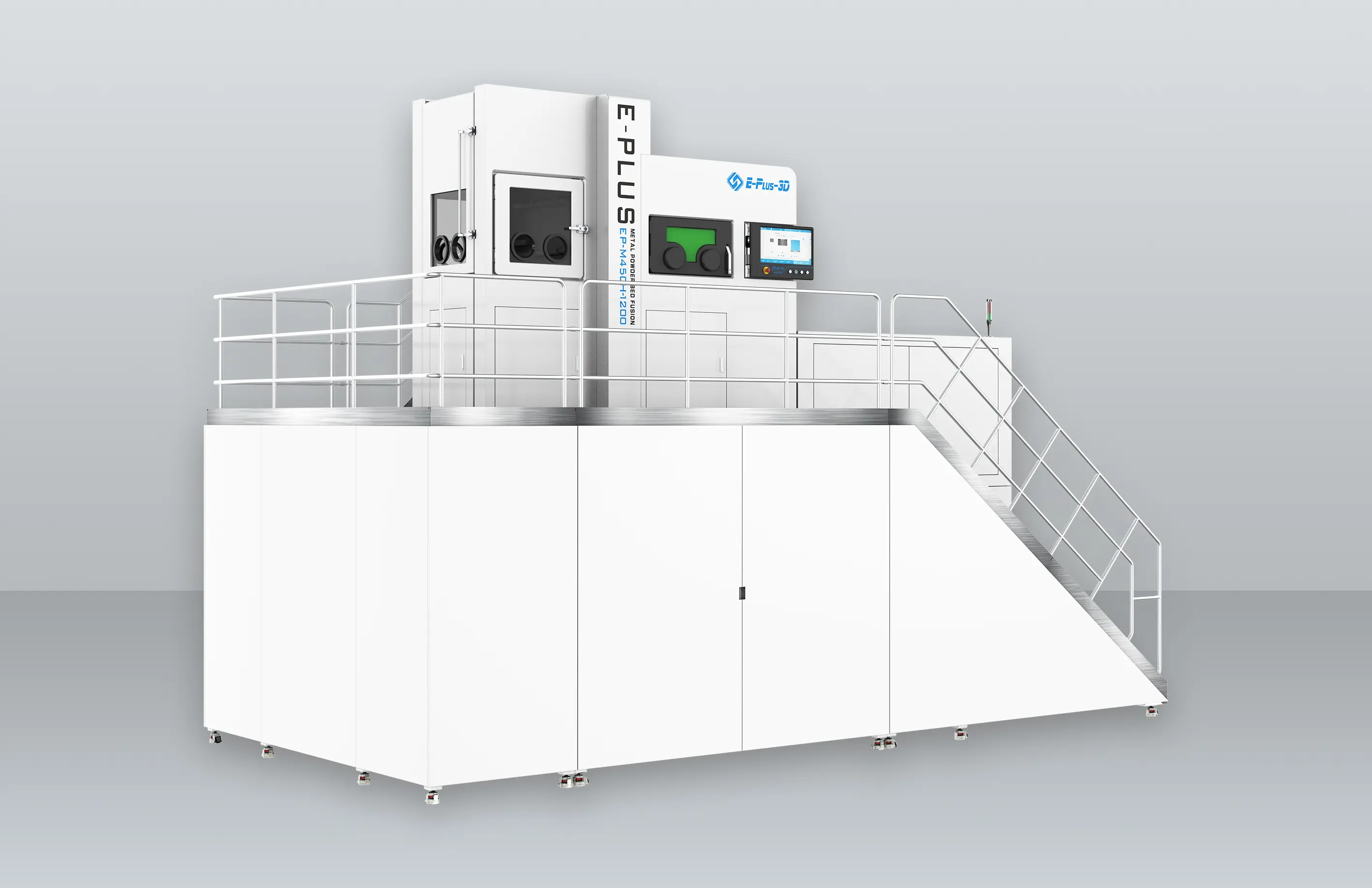

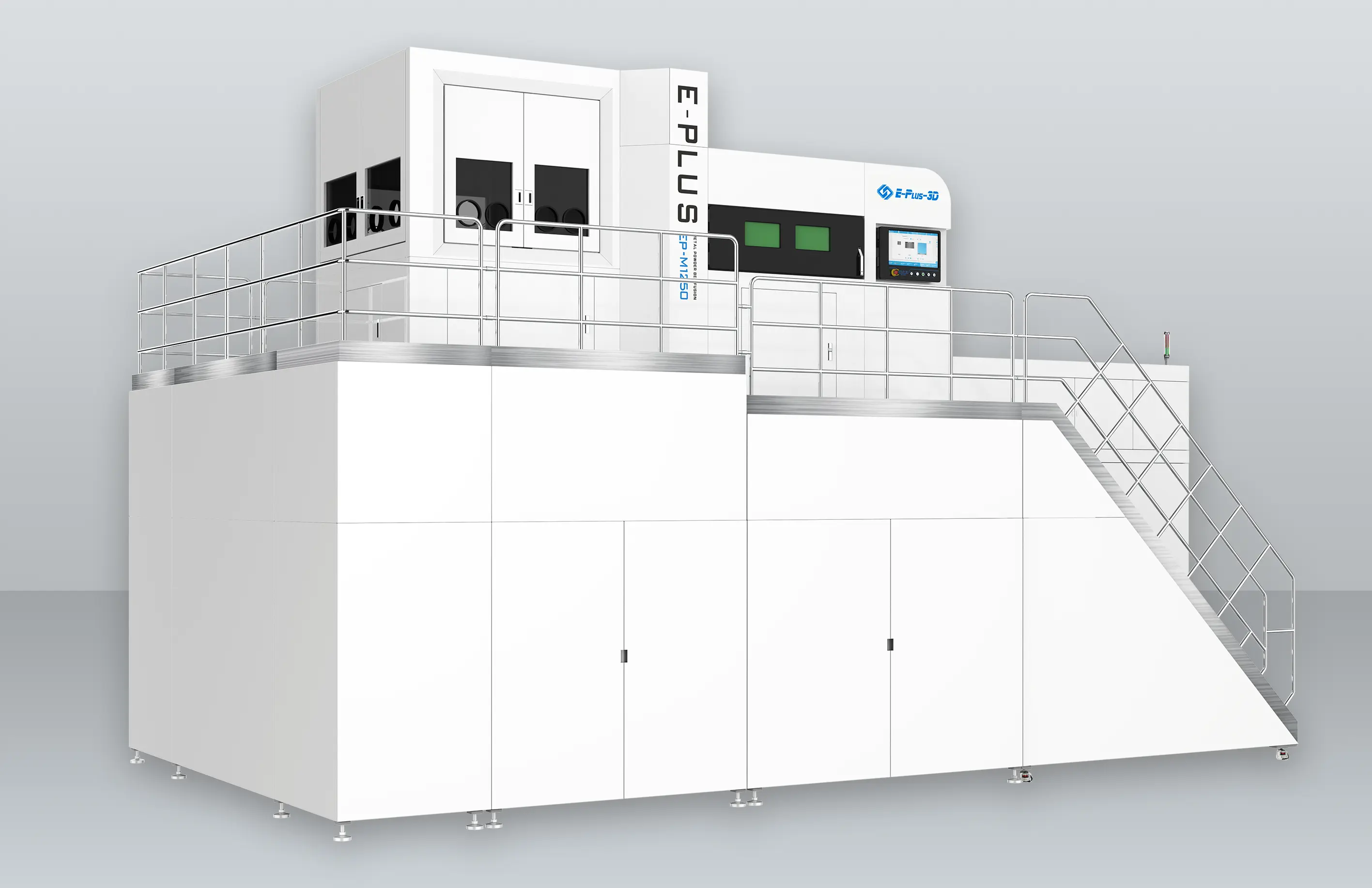

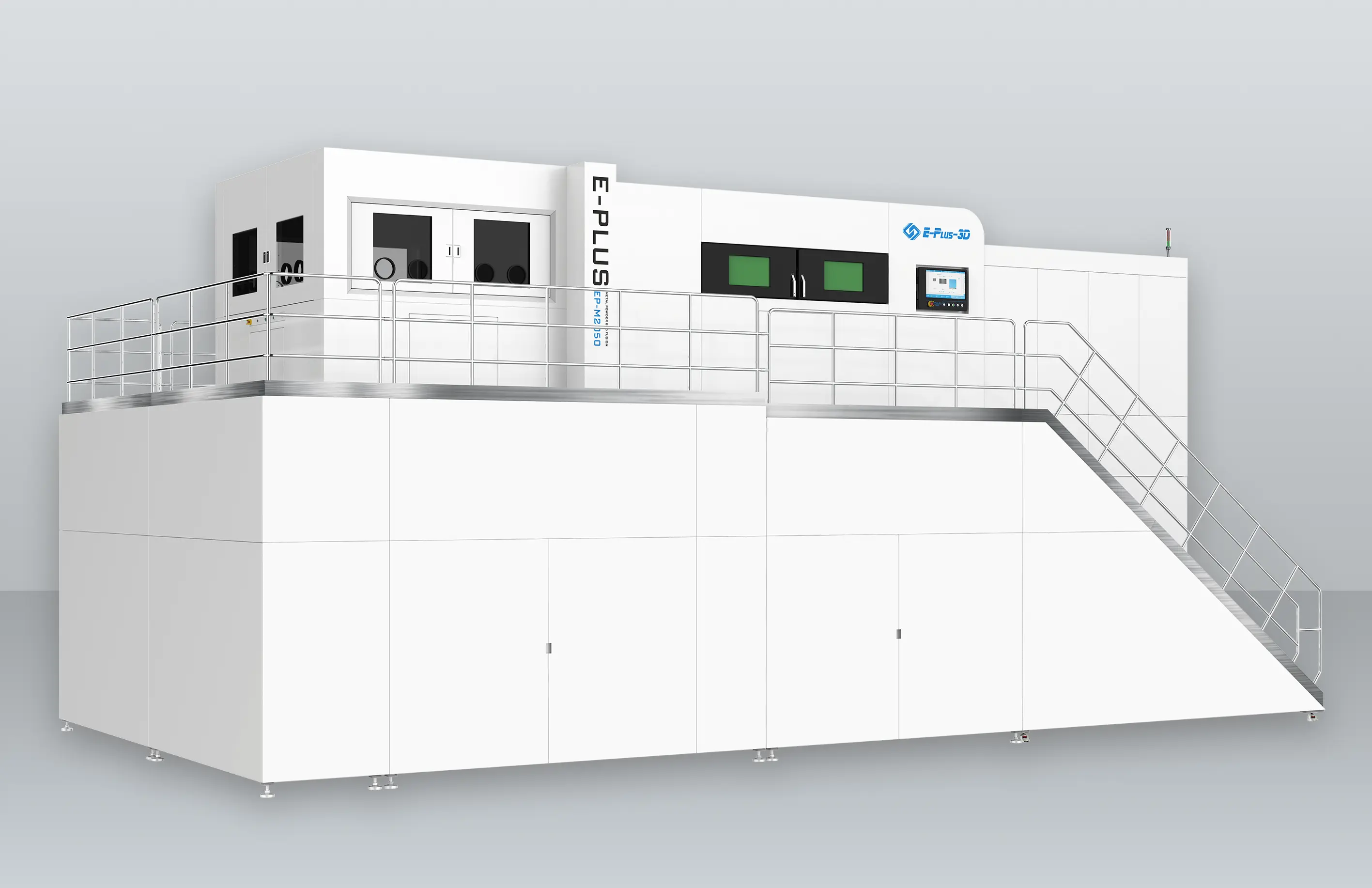

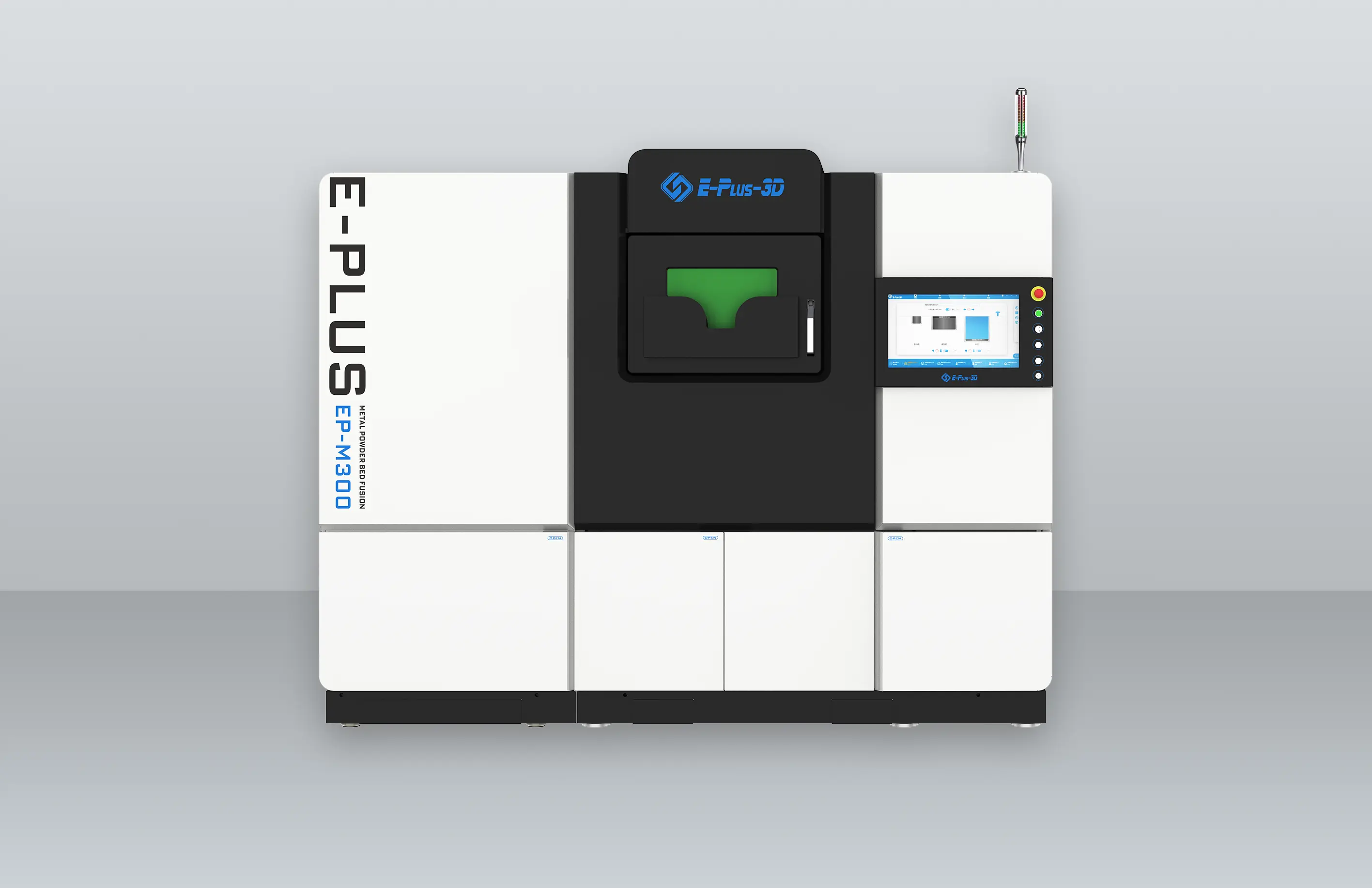

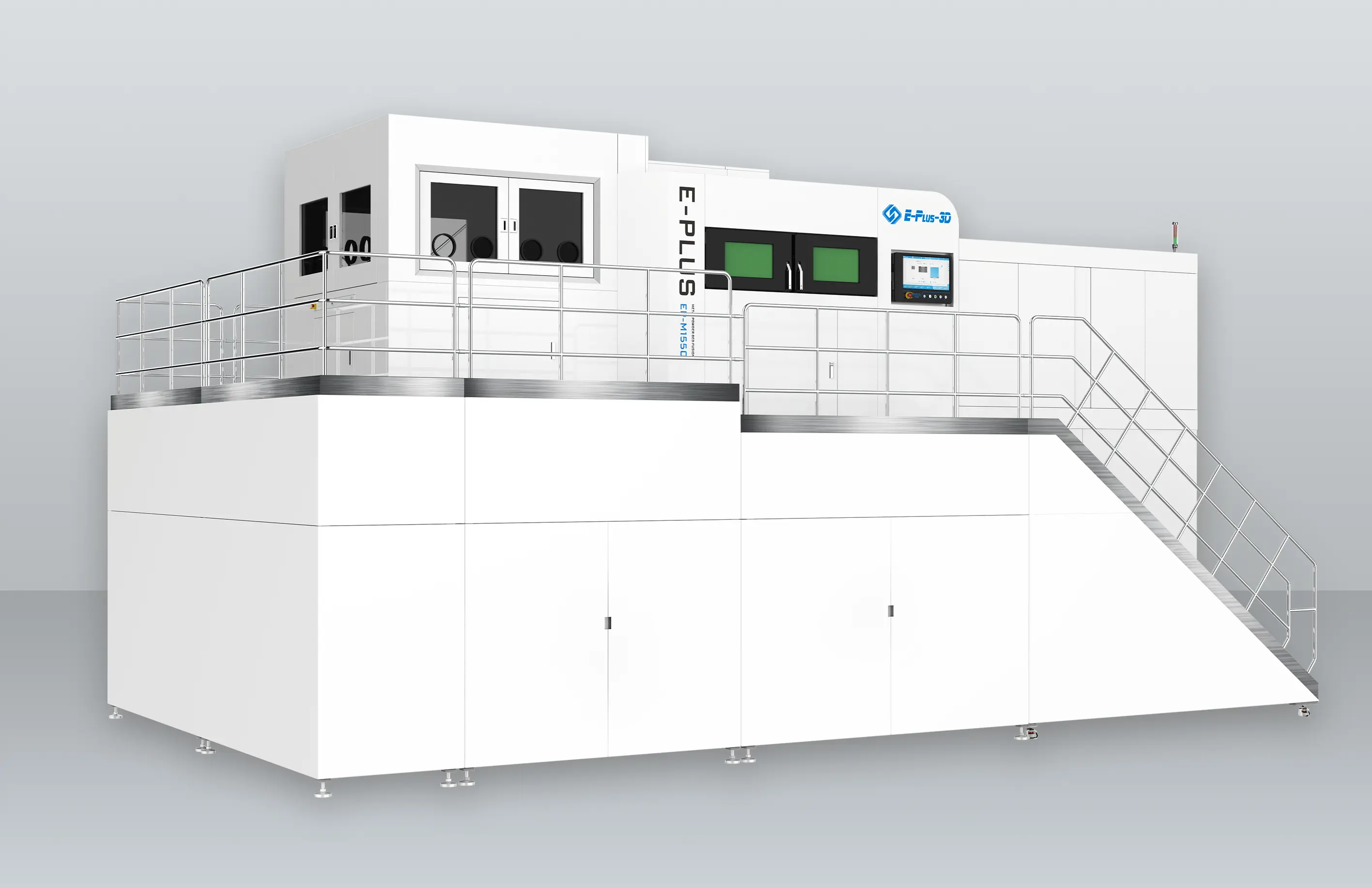

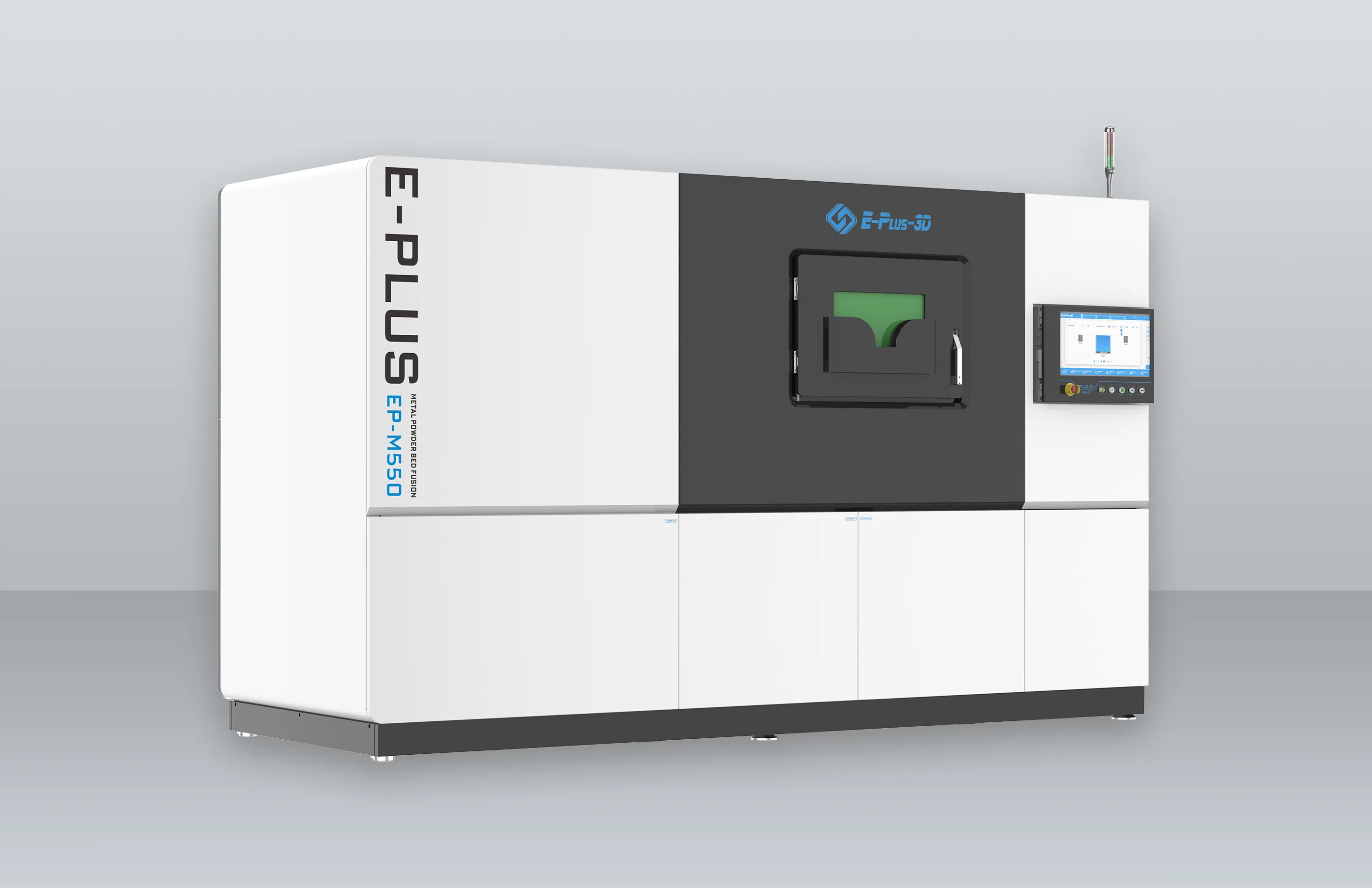

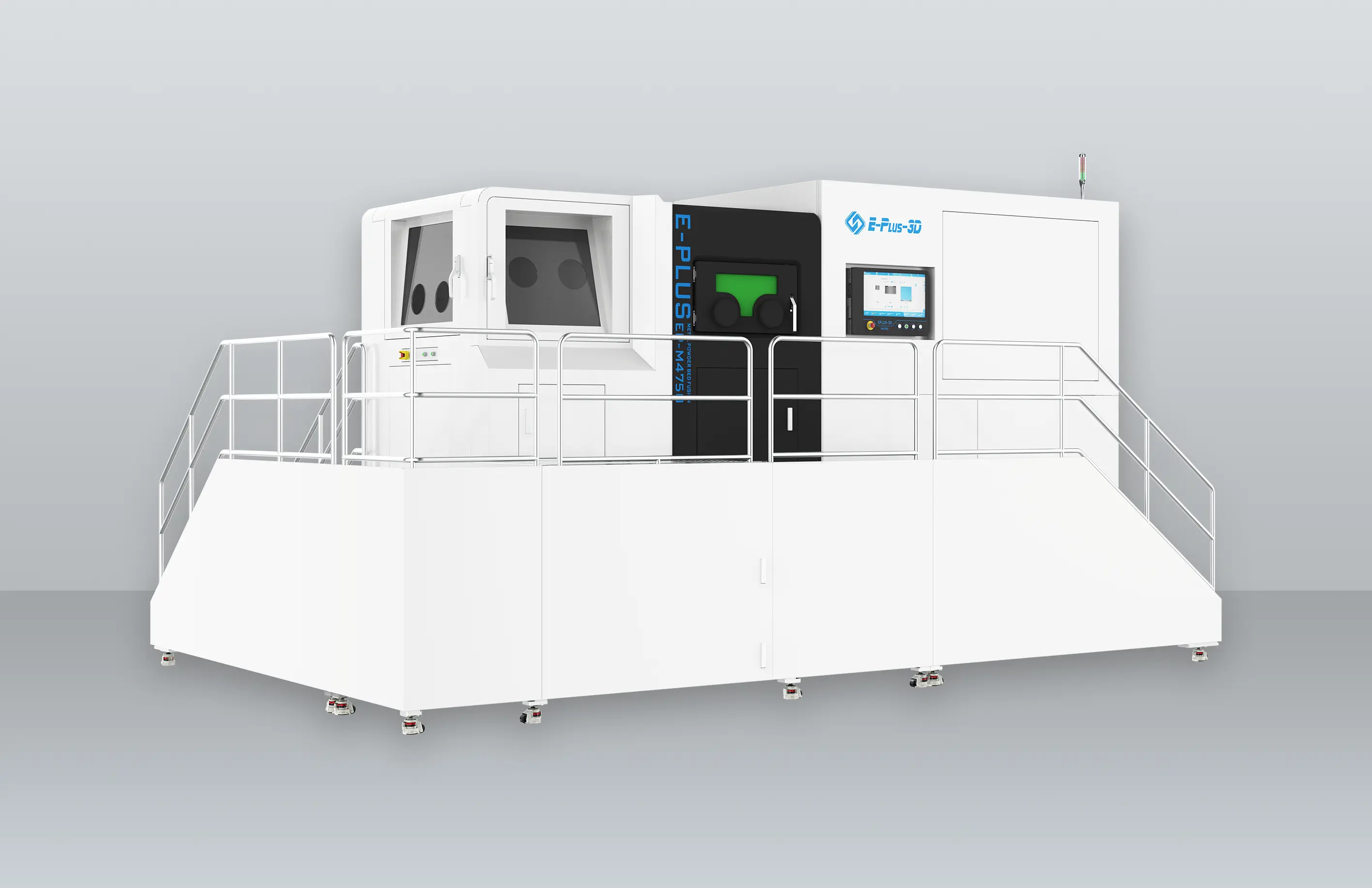

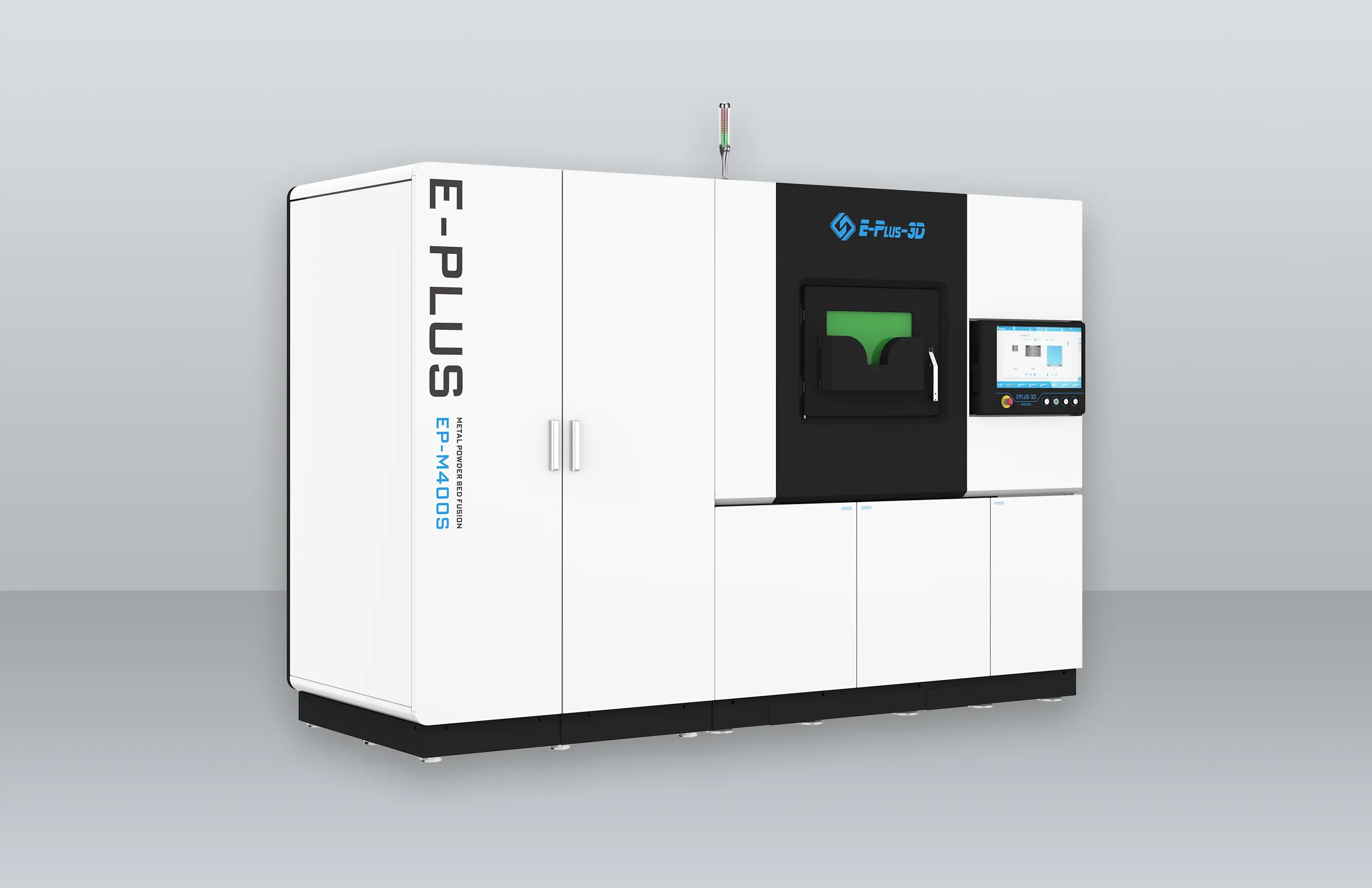

Manufacturing on EP-M400S

Figure 4 - Printed Engine and Swirl injectors inside the EP-M400S

The manufacturing process was carried out on the EP-M400S quad-laser LPBF system, equipped with four 700 W lasers. A 60 µm layer thickness was used to achieve fine internal channel resolution and the smooth surfaces required for the injector’s performance. Eplus3D’s DfAM experience and input ensured that the design was optimised for printability, minimising the risk of defects and reducing post-processing requirements. Printing the engine as two integrated assemblies allowed for a substantial reduction in part count and assembly complexity compared to conventional manufacturing methods.

Testing and Results:

UCL Rocket's first regeneratively cooled engine, Excelsior, was successfully hot-fired at Airborne Engineering Ltd. for Race 2 Space 2025, withstanding three hot-fire tests to achieve its target thrust of 5 kN.

Figure 5 - Hot Firing Test performed at the Race2Space Event

Engine specifications |

Propellants | Isopropyl Alcohol (IPA) / Nitrous Oxide (N₂O) |

Design Mass Flow Rate | 2.49 kg/s (Oxidiser-to-Fuel Ratio: 3.2) |

Design Chamber Pressure | 25 bar |

Design Target Thrust | 5 KN |

Test 1 Highlights:

• Target IPA mass flow rate achieved.

• Achieved 90% of target N2O mass flow rate; tank pressure increased to drive more mass flow for subsequent tests.

• Average pressure drops from fuel inlet to injector measured to be 0.9 bar, within 6.6% of CFD simulation predictions.

• Minor IPA and N2O leakage due to faulty seals (replaced post-test).

Test 2 Highlights:

• Target N2O mass flow rate achieved.

• Partial blockage in 0.84mm IPA injector orifices due to residual swarf in injector manifold. Blockage cleared mid-burn.

Test 3 Highlights:

• IPA and N2O mass flow rates throttled up proportionally to achieve target thrust of 5 kN, peaking at an average of 4.92 kN in the last 100ms of the burn.

• Maximum possible N2O mass flow rate achieved within feed system limits.

• Achieved a maximum Specific Impulse of 174.47 s and c* Efficiency of 85.66%, the best across all 3 tests.

Figure 6 – Firing test overlayed video, credits to Tom Danvers and the University of Sheffield's Sunride team (@project_sunride) for their open-source liveplot video overlay tool

In competition, Excelsior placed fourth in the Nitrous Bipropellant category and was one of only eight engines out of seventeen to survive all hot-fire tests. The project highlighted several key lessons, including the importance of thorough cleaning to prevent injector blockages, the need for reliable sealing solutions, and the capability of LPBF to enable rapid, high-performance aerospace hardware development in a student-led environment.

The success of Excelsior demonstrates that advanced LPBF in AlSi10Mg can produce high-performance regeneratively cooled rocket engines within the constraints of a university project. By combining innovative design, optimised manufacturing, and rigorous testing, the collaboration between Eplus3D and UCL Rocket shows how additive manufacturing can accelerate aerospace propulsion development.